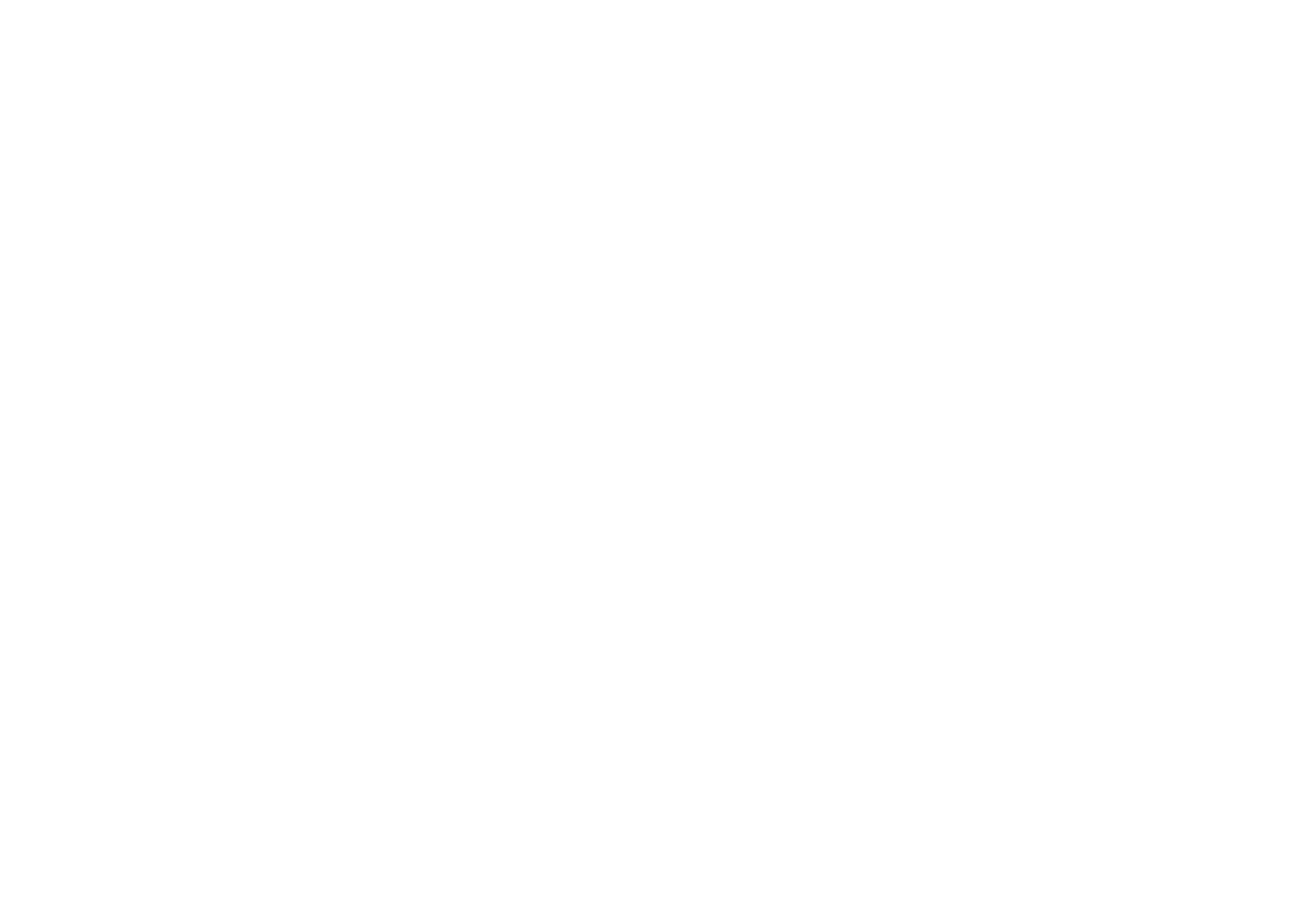

Magnetic Particle Inspection (MPI)

We're the experts in Magnetic Particle Inspection. Let us help you ensure your product is defect-free.

REQUEST A QUOTE

To cut down on your waiting time, simply request a quote online.

We will get back to you as soon as possible

Please try again later

Met-L-Test Laboratory is an independent family owned business since 1958. We are a Non Destructive Testing facility specializing in the Penetrant Testing (FPI), Magnetic Particle Testing (MPI), and Radiographic Testing (XRay) methods.

-

All of our inspectors are trained and certified

Our inspection personnel are all qualified and certified in accordance with NAS410 requirements and maintain various levels of certifications for flight safety, primary and critical characteristic parts.

-

Our objective and culture is to meet or exceed our customer's expectations

Met-L-Test Laboratory's primary goals and objectives are to supply a high level of quality and service while maintaining a quick turn around time at competitive prices.

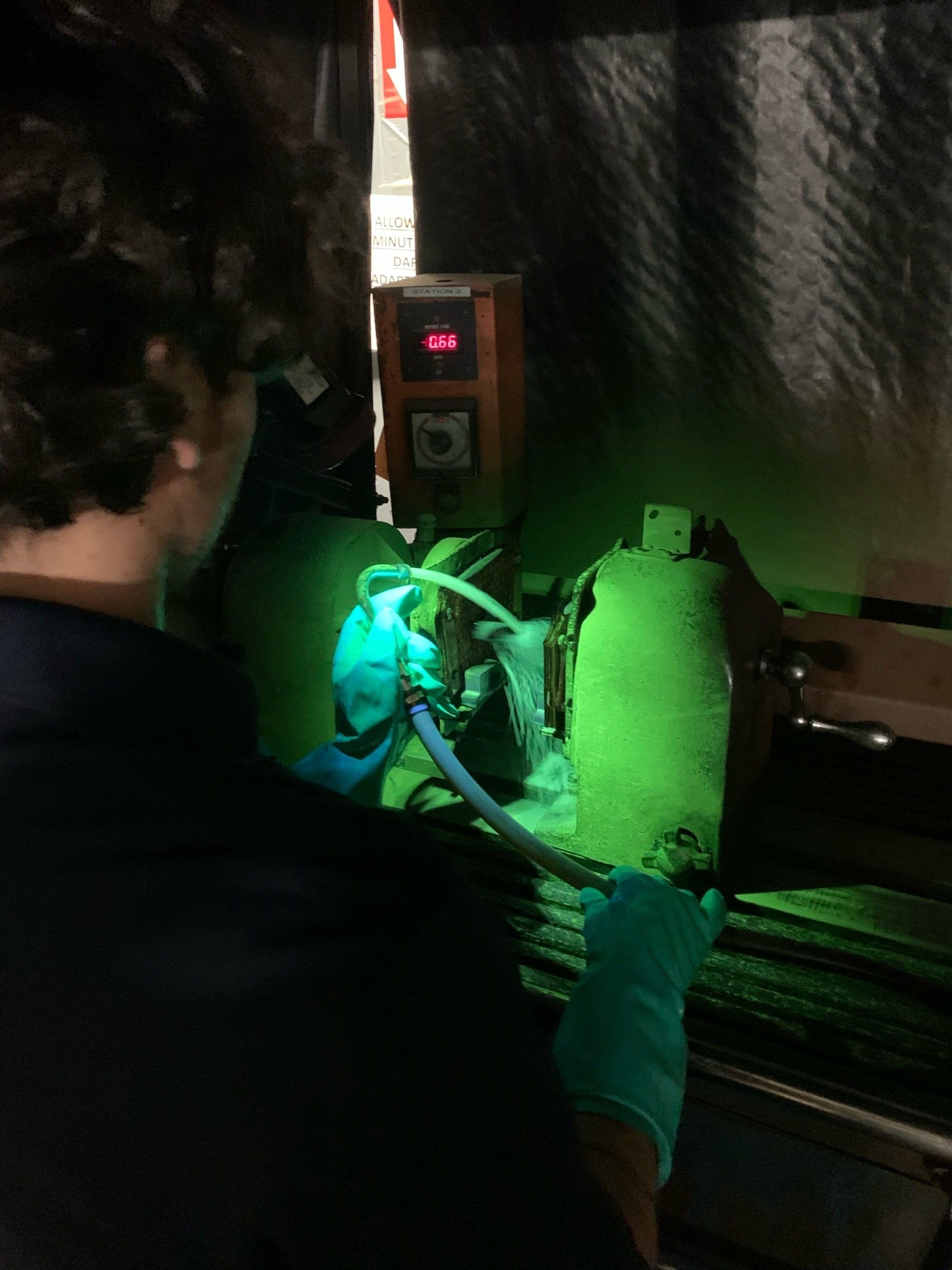

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) method used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. It is a fast, reliable, and cost-effective way to ensure the integrity and reliability of products and equipment made of ferromagnetic materials.

During MPI, a magnetic field is induced in the component being tested. Ferromagnetic iron oxide or iron oxide-coated magnetic particles are then introduced to the surface. The particles are attracted to areas of flux leakage where they form an easily visible indication of the location of the defect.

MPI is often used to inspect welds, castings, and forged components in industries such as aerospace, automotive, power generation, and oil and gas. It can be performed on a wide range of components, including welds, castings, and forged components, and is suitable for both small and large components.

MPI is also a highly sensitive method, able to detect small defects that may not be visible to the naked eye. If you are in need of reliable and accurate testing for your ferromagnetic components, our team of experienced technicians will ensure that your components meet the highest standards of quality and safety.

Advantages

- Non-destructive: MPI is a non-destructive testing method, meaning it does not alter or damage the component being tested in any way.

- Versatility: MPI can be used on a wide range of ferromagnetic components, including welds, castings, and forged components. It is suitable for both small and large components.

Main Office

115 Browning Street

Stratford, CT 06615

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Needed services can be provided on weekends but must be scheduled

Website powered by AdsNeeded