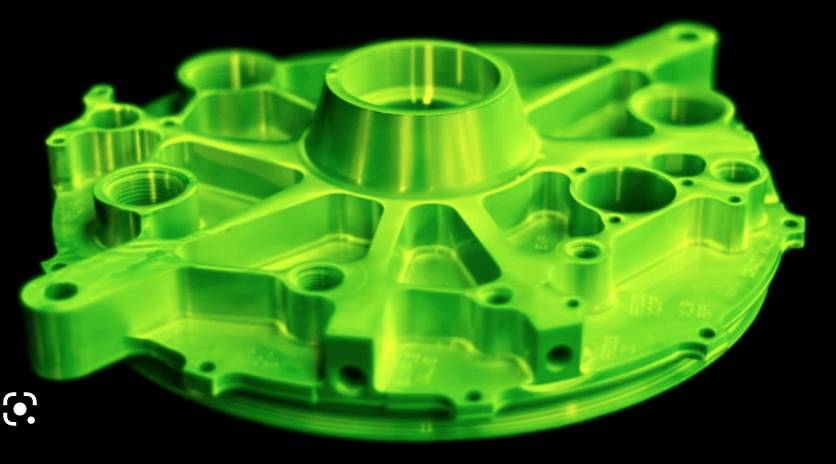

Fluorescent Penetrant Inspection (FPI)

We're the experts in Fluorescent Penetrant Inspection. Let us help you inspect your product for any possible defects.

REQUEST A QUOTE

To cut down on your waiting time, simply request a quote online.

Met-L-Test Laboratory is an independent family owned business since 1958. We are a Non Destructive Testing facility specializing in the Penetrant Testing (FPI), Magnetic Particle Testing (MPI), and Radiographic Testing (XRay) methods.

Fluorescent Penetrant Inspection (FPI)

FPI is a non-destructive testing method used to detect surface-breaking defects in metallic and non-metallic materials. It is commonly used to inspect castings, forgings, and welded components in industries such as aerospace, automotive, and power generation.

During FPI, a fluorescent dye is applied to the surface of the component being inspected. The dye is then "developed" using a developer, which helps to draw the dye into any surface-breaking defects. The component is then exposed to ultraviolet (UV) light, which causes the fluorescent dye to fluoresce (glow) brightly. This makes it easy for the inspector to identify the location of any defects on the component's surface.

One of the benefits of FPI is that it can detect very small defects that may not be visible to the naked eye.

At Met-L-Test Laboratory, we are experts in FPI and have the skills and equipment necessary to provide accurate and reliable testing services for your components at our facility or directly on site. Contact us today to learn more about how FPI can benefit your business.

Advantages

- Sensitivity: FPI is capable of detecting very small defects, as small as 0.1 mm in some cases.

- Versatility: FPI can be used on a wide range of materials, including metals, plastics, ceramics, and composites.